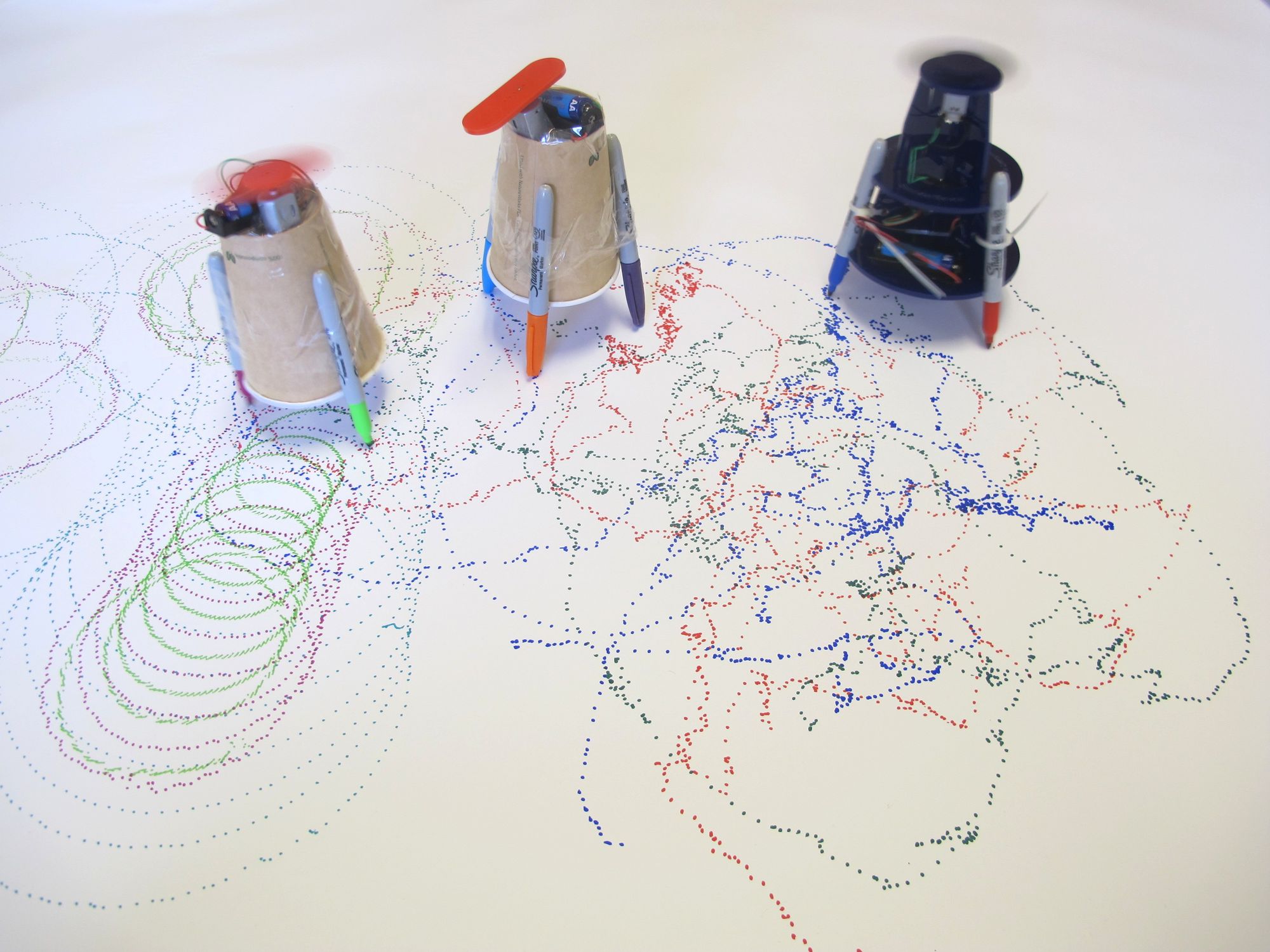

Doodlebots are simple to construct drawing robots that create random coloured patterns as they vibrate around on a sheet of paper. I’ve run a couple of workshops on making doodlebots and even a workshop on running and preparing for doodlebot courses.

It’s a really great activity; the doodlebots are simple enough (tape things onto a cup) that anyone can get stuck in within moments of starting, but it’s complex enough and there’s enough variables that it’s open ended enough that as soon as you’ve tested it, you’re already seeing a few more ways to improve yours. At about £3 per kit, it’s also low enough cost that everyone who makes one can take theirs home with them.

Parts

For each participant:

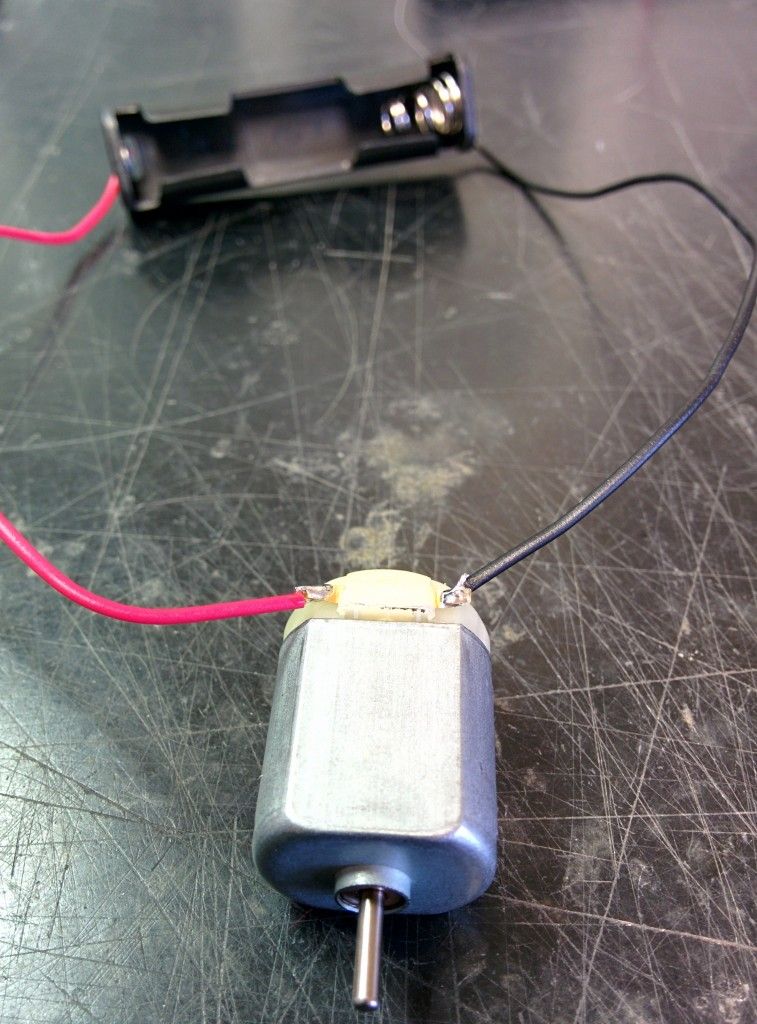

- a small motor soldered to a single AA battery pack

- an AA battery

- an offset weight Spinner (or a 2mm shaft gear and an adhesive weight)

- cardboard cup

- 3 felt tip pens

Allow 100 kits per 2-3 hour session for open access events.

You should be able to source these at up to £3 per kit if you shop around. Remember if you’re ordering on line that you’ll need to order at least 1 week before the event to get everything delivered and assembled on time.

If you’re having trouble, or you don’t want to source or construct your own kits, I can supply them at £3 per kit plus delivery. Please contact me for details: contact@def-proc.co.uk

For the group:

- tape

- blue tack

- a large roll of paper

- wide masking tape

Recipe

Lay down a large area of paper on the floor, taping pieces together to give a large enough area for your doodlebots to run in.

To build a doodlebot:

- Place the cup upside down, so the base is at the top, and the rim is at the bottom.

- Tape the motor to the base of the cup, making sure the spinner is free to rotate

Tape the battery holder to another part of the cup - Tape each of the three felt tip pens to the cup so the uncovered ends reach below the rim and the whole doodlebot will rest on the pen nibs.

- Insert the battery into the battery holder to start the motor spinning and place on a large piece of paper to start drawing a pattern

- Adjust the pens, motor, battery holder and spinner orientation and position as required to keep the doodlebot from falling over in normal use.

Making Doodlebot Kits

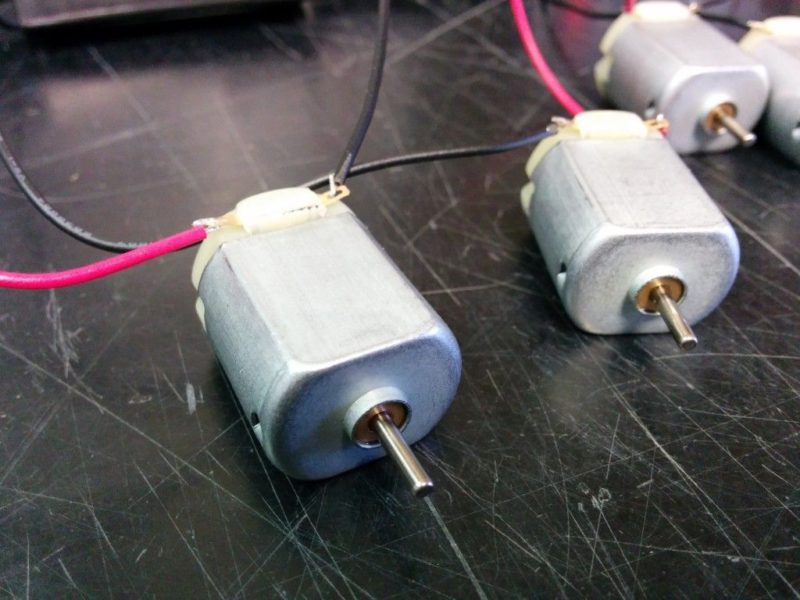

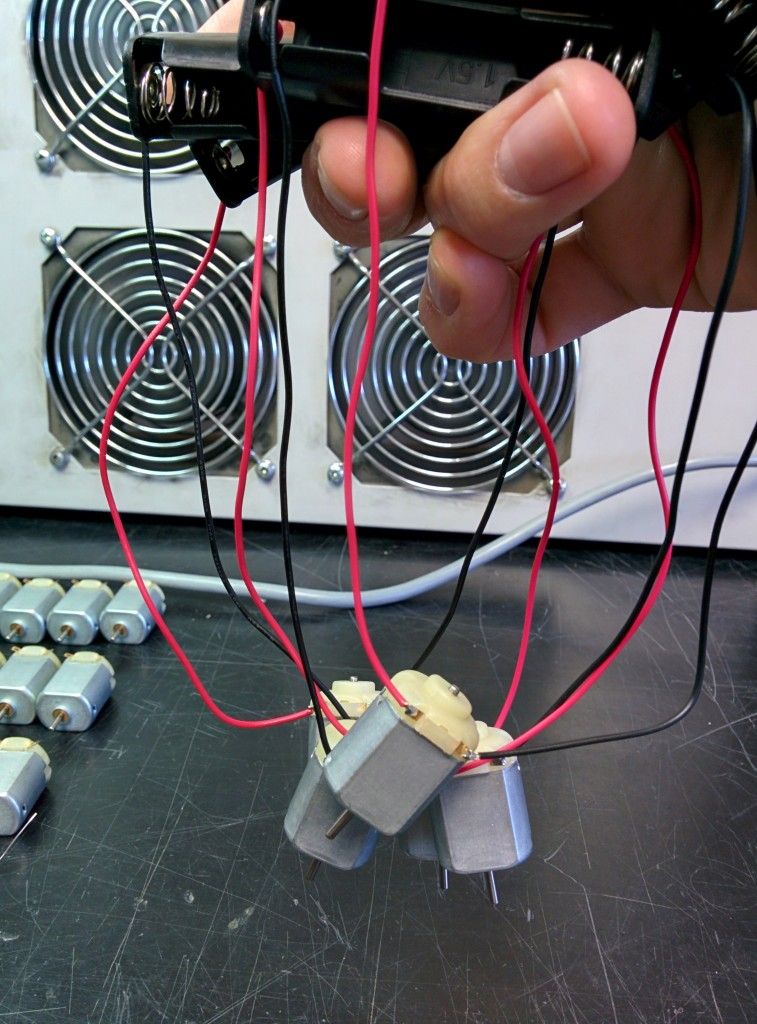

The key bit to the doodlebot kit is the soldered motor and battery holder with the push-on spinner. I have tried to do this with taping the connections and it doesn’t work reliably, and soldered battery connectors allow for a switch (battery in/out).

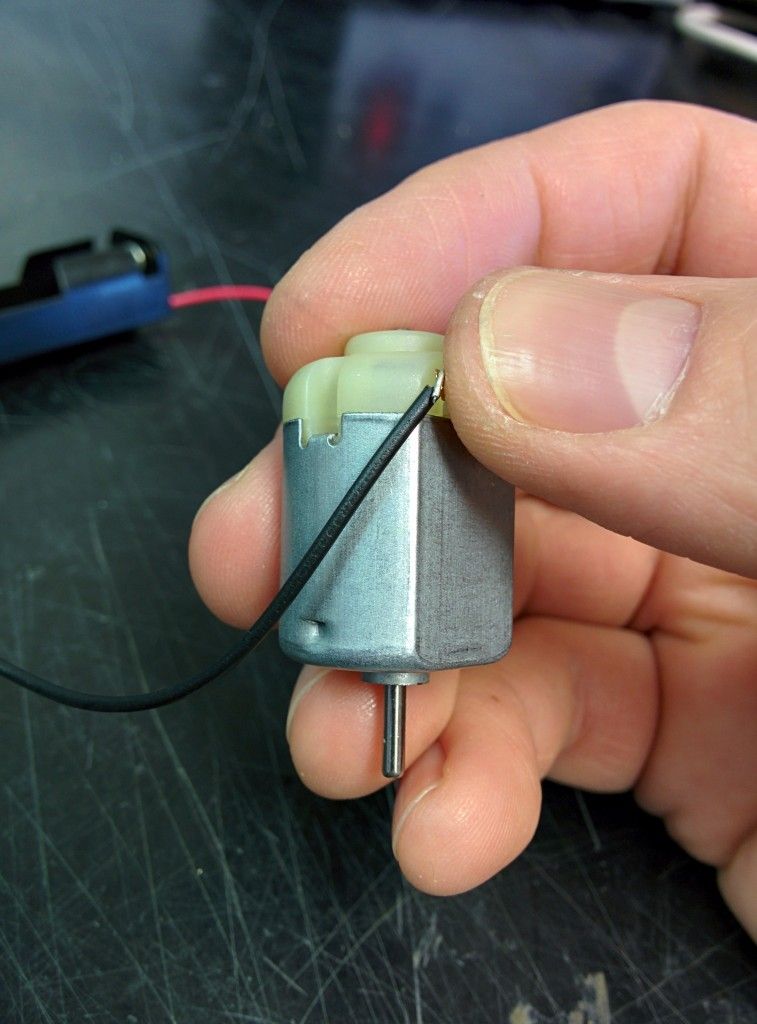

When I first tried soldering the motors, I had a few that wires break off from the motor tiny motor tabs, or the tabs get pulled off — kids aren’t always the most delicate builders, and the area around the solder joint is the weakest. All it needed was a little reinforcement to protect that area by encapsulating it in hot glue to make the motor battery holder combo much more reliable.

If you have a group of older makers, soldering the motor to the battery holder is a great activity too. Maybe get an older group to make 2 per person, and you get enough for another group of youngsters.

I have access to a laser cutter, so I cut my spinners. If you don’t, there are a set of nylon gears that are designed to be a push fit onto the 2mm motor shafts. One of these in the larger diameters (31 teeth) and some blue tack to create an offset weight works too.

If you’d like me to make spinners for your doodlebot event, I can supply them at 50p each plus delivery, or they are included as part of the £3 per kit. Please contact me for details: contact@def-proc.co.uk

To make the spinner/motor/battery connection you will need:

- soldering iron

- solder

- glue gun

- glue gun sticks

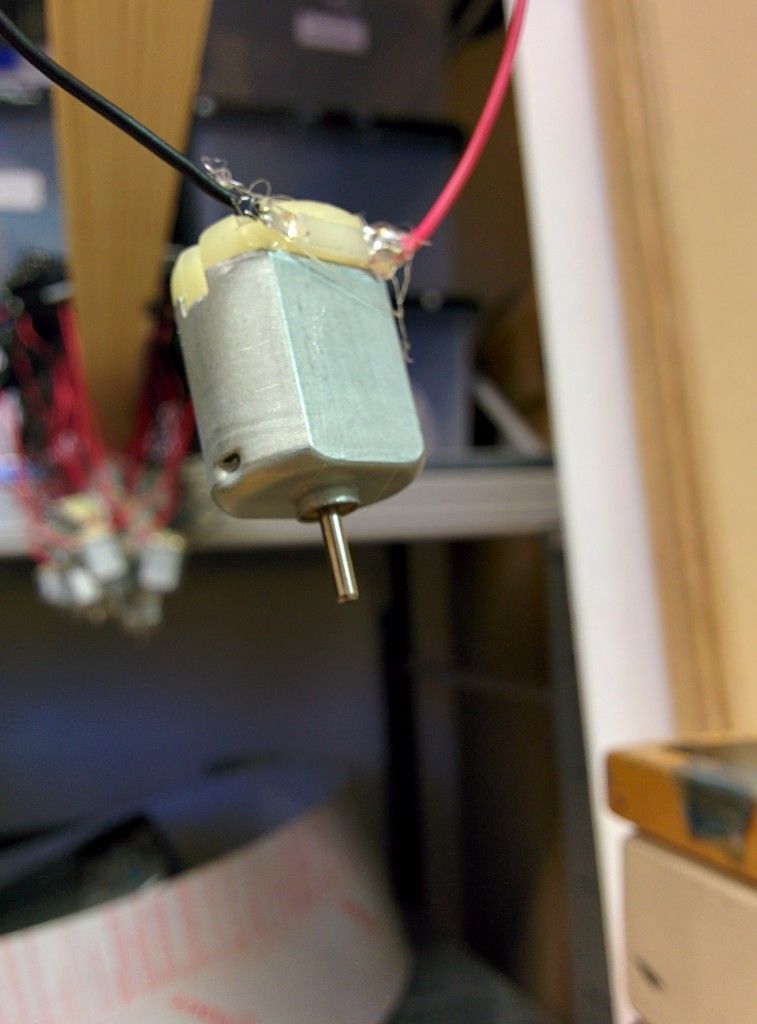

- small motor (a flat, low torque, 1.5-6V DC 13,000rpm motor)

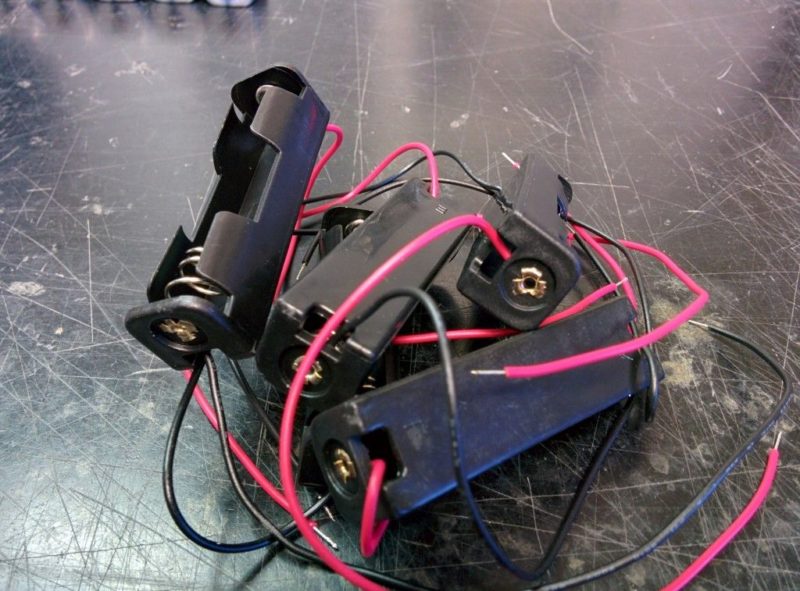

- AA battery holder with leads

Working in batches of 5:

- push one wire on the through each motor tab and fold over to hold it in place

- solder each wire to the tab

Then once you have 25 soldered motors, in batches of 5:

- apply a blob of glue gun glue around the tab, solder connection and the end of the wire to reduce the risk of the joint breaking in use.